From the Bench: Mainspring Mechanics

What is a Watch Mainspring?

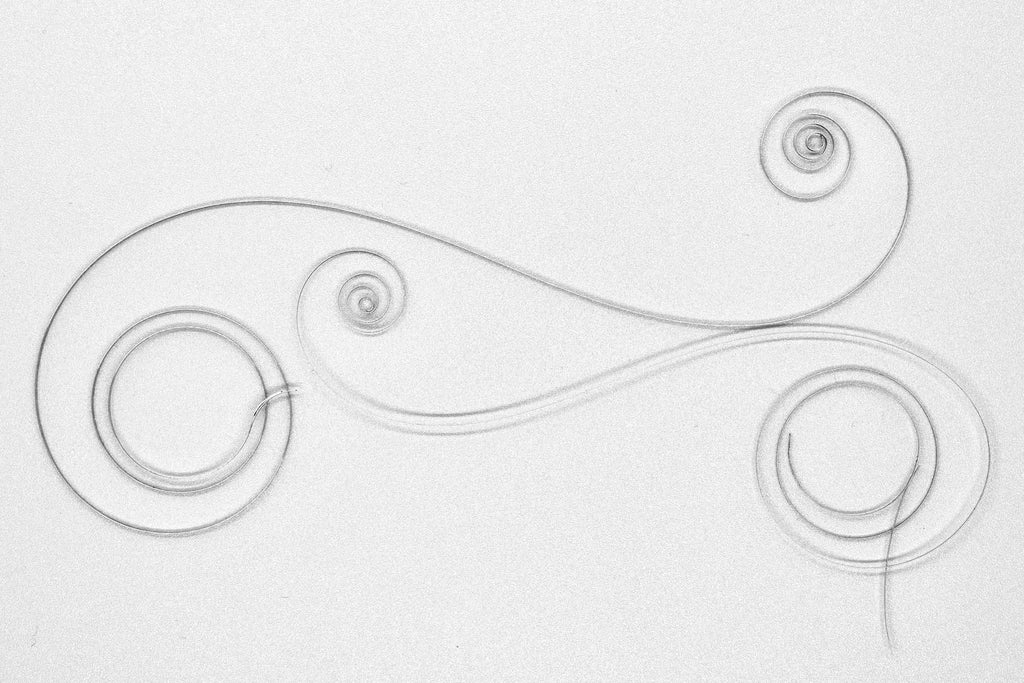

Mainsprings are what make your watch tick consistently. They consist of a flat spring steel band that's coiled when wound, storing energy to keep your watch ticking.

Mainsprings come in two main types, traditional and automatic.

Automatic Mainspring

A Quick History of Mainsprings